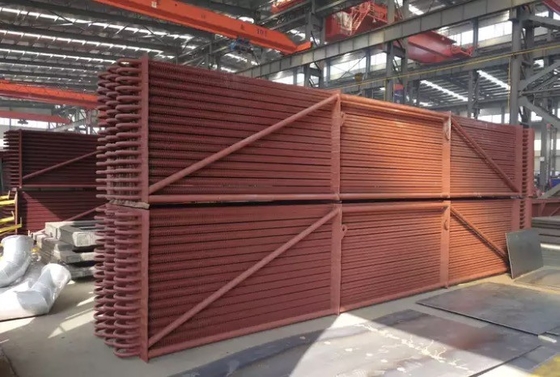

SA210A1 Carbon Steel Biomass Steam Boiler Parts Stack Economizer

Manufacturing Process:Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →Bending tube→Assembly →Inspection →RT→Heat treatment (annealing)→Hydraulic pressure test→Painting→ Packaging

Specifications

| Description |

Boiler economizer |

| Material |

Alloy steel(SA213T22), Carbon steel(SA210C ) etc. |

| Material standard |

ASTM, EN or ISO etc. |

| Dimension |

Customization |

| Weight |

Min: 10 ton Max.:200 ton |

| Manufacturing process |

Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →Bending tube→Assembly →Inspection →RT→Heat treatment (annealing)→Hydraulic pressure test→Painting→ Packaging |

Boiler economizer

Boiler Economizer is the energy improving device that helps to reduce the cost of operation by saving the fuel. The economizer in Boiler tends to make the system more energy efficient. In boilers, economizers are generally designed to exchange heat with the fluid, generally water. The exhaust from the boilers is generally in the temperature range of 200°C – 250°C, so there are a huge amount of losses from the boiler if any heat recovery devices are not installed after it. Boiler Economizer that suit your boiler system and will increase its overall efficiency from 3% – 5%. Increase in boiler efficiency will save a lot of your operating cost and eventually will prolong the life of your boiler system.

We can manufacture three types of boiler economizer, bare tube economizer, H-finned tube economizer and spiral finned tube economizer.

|

|

Alloy steel(SA213T22), Carbon steel(SA210C ) etc.

|

|

|

ASTM, EN or ISO etc.

|

|

|

Customization

|

|

|

Min: 10 ton Max.:200 ton

|

|

|

Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →Bending tube→Assembly →Inspection

→RT→Heat treatment (annealing)→Hydraulic pressure test→Painting→ Packaging

|

Production Descriptions

Boiler Economizer is the Energy improving device that helps to reduce the cost of operation by saving the fuel. The economizer in Boiler tends to make the system more energy efficient. In boilers, economizers are generally designed to exchange heat with the fluid, generally water. The exhaust from the boilers is generally in the temperature range of 200°C – 250°C, so there are a huge amount of losses from the boiler if any heat recovery devices are not installed after it. Boiler Economizer that suit your boiler system and will increase its overall efficiency from 3% – 5%. Increase in boiler efficiency will save a lot of your operating cost and eventually will prolong the life of your boiler system.

Classification

We can manufacture three types of boiler economizer, bare tube economizer, H finned tube economizer and spiral finned tube economizer. H-finned tube economizer is high efficient heat exchanger economizer which is consisted of H-finned tubes.

Compared with bare tube economizer, H-finned tube economizer can enlarge the heat exchange area and reduce the number of tubes. It also can increase the flue gas flow area in order to reduce the flue gas flow speed and abrasion.

H-finned tube can be made as double H finned tubes , with high rigidness to fit long tube row.

The spiral finned economizer is a newly designed heat transfer equipment, consists of spiral fin tubes to overcome the serious abrasion and short service time.

Company Information

Suzhou ORL Power Engineering Co., Ltd.is located in Suzhou, Jiangsu Province.

ORL Power is a leading company and exporter of industrial boilers,power plant boilersand boiler parts (including steam drum, membrane waterwall panel,header,economizer, evaporator, superheater,H-fin economizer, spiral fin tube, air preheater, heat pipe, flue etc.), seamless steel tubes/pipes and ERW steel pipes.ORL provides our customer with full range of services including boiler design, fabrication, installation and commissioning, boiler maintenance, and supervision at site. Our product and service include design and manufacture industrial boilers, pressure vessels and tanks, and pressure parts for power plant boilers (600MW, or 1000MW).

Boiler Product Test

Impact test,The scene to examine the water-wall,Industrial TV monitoring,Snake-like pipe water pressure test,Header endoscopic detection,Header weld inspection

Packaging & Shipping

Certifications

We have our boiler manufacturing plant, and obtain ISO9001:2008, ISO3834, ASME S, U and GB stamp.

Company Business

Our products have been wildly used in power plants and large international companies overseas.

Such as USA, Brazil, Porto Rico, Guatemala, Spain, Demark, Norway, Turkey, India, Korea, Australia, Middle East, Southeast Asia etc.

Trading Process

ORL offers prompt response, professional products, and all-around service to our customers. Our experienced sales team and engineers are waiting for your enquiry and ready to provide sincere service. We cordially welcome domestic and overseas friends to visit our company and manufacturing bases, and look forward to building up long-term, mutual cooperative relationship with you.

FAQ

1. How to order?

Welcome come to our factory for inspecting and discussion the technical details.

2. Why choose us?

We are boiler and boiler parts(boiler drum, boiler waterwall panel, boiler economizer, boiler header, boiler cyclone separator, boiler flue pipe, boiler air preheater, boiler pipe, boiler tube)manufacture and we are one of the best suppliers in China.

We ensure the deliver time, high quality, and the best after-sale service for you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!